Beryllium copper (BeCu) is a widely used alloy known for its exceptional strength, conductivity, and corrosion resistance. It plays a crucial role in industries such as aerospace, electronics, and automotive manufacturing. However, concerns regarding its safety have led to misconceptions about its potential health risks.

This article explores the safety of beryllium copper, debunking myths while addressing valid concerns. We will discuss health risks, regulatory guidelines, and best practices for handling this material safely.

What is Beryllium Copper?

Understanding Beryllium Copper Alloy

Beryllium copper is a high-performance copper alloy containing 0.5% to 3% beryllium. It is valued for its unique combination of mechanical and physical properties, including:

High strength: Comparable to steel while retaining the machinability of copper.

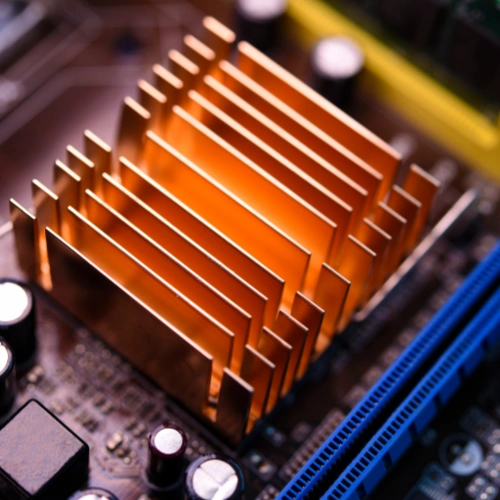

Excellent electrical and thermal conductivity: Ideal for electronic connectors and thermal management applications.

Corrosion and fatigue resistance: Suitable for extreme environments, such as marine and aerospace settings.

Common Applications of Beryllium Copper

Electronics: Used in connectors, switches, and circuit board components.

Aerospace and defense: Applied in aircraft landing gear bushings and military-grade tools.

Automotive: Found in ignition components and fuel injection systems.

Oil and gas industry: Utilized for non-sparking, non-magnetic tools in hazardous environments.

Health Risks of Beryllium Copper

Key Safety Concerns and Health Hazards

While beryllium copper is safe in solid form, exposure to airborne beryllium particles poses health risks, particularly in industrial settings where machining, grinding, or welding occurs.

Potential Health Issues

Chronic Beryllium Disease (CBD): A lung condition caused by prolonged inhalation of beryllium dust or fumes. Symptoms include coughing, shortness of breath, and fatigue.

Acute Beryllium Disease: A rare condition resulting from high exposure levels, causing lung inflammation similar to pneumonia.

Skin Sensitization: Direct contact with beryllium dust may cause allergic reactions in some individuals.

Regulatory Guidelines for Exposure

OSHA (Occupational Safety and Health Administration): Sets a permissible exposure limit (PEL) of 0.2 µg/m³ over an 8-hour work shift.

NIOSH (National Institute for Occupational Safety and Health): Recommends stricter exposure controls for high-risk work environments.

Is Beryllium Copper Safe for Everyday Use?

Safety in Context: Industrial vs. Consumer Applications

The level of risk associated with beryllium copper depends on how it is used.

Industrial Handling (High Risk): Processes such as cutting, grinding, and welding release airborne particles, increasing exposure risk. Proper protective measures are necessary.

Consumer Products (Low Risk): Finished products like tools, connectors, and musical instrument components are generally safe because beryllium remains bound within the alloy, minimizing exposure risks.

Scientific Perspective on Safety

Studies show that beryllium copper does not leach harmful amounts of beryllium in typical consumer applications. Thus, items like jewelry or everyday tools pose minimal health concerns.

Safe Handling Practices for Beryllium Copper

Best Practices for Industrial Workers

To mitigate health risks, industries employing beryllium copper must follow strict safety protocols:

Personal Protective Equipment (PPE): Workers should wear gloves, respirators, and protective clothing when handling or machining beryllium copper.

Ventilation Systems: Installing proper exhaust ventilation reduces airborne beryllium dust.

Workplace Training: Employees should be educated on beryllium exposure risks and safety procedures.

Hygiene Measures: Washing hands and changing clothes after handling beryllium copper prevents secondary exposure.

Regulatory Compliance and Alternatives

Global Regulations and Safer Substitutes

Due to health concerns, global regulatory bodies have implemented restrictions on beryllium copper use in certain industries:

EU REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals): Enforces restrictions on beryllium in consumer products.

RoHS (Restriction of Hazardous Substances Directive): Limits hazardous substances in electrical and electronic equipment.

Safer Alternatives to Beryllium Copper

Phosphor Bronze: Provides good conductivity without beryllium.

Aluminum Bronze: Offers corrosion resistance and moderate strength.

Nickel-Copper Alloys: Used in marine and chemical applications as a substitute.

While alternatives exist, beryllium copper remains unmatched in certain applications requiring extreme durability and conductivity.

Beryllium copper is an essential material with widespread applications. While industrial exposure requires strict safety measures, everyday consumer use is generally safe. Companies handling beryllium copper should follow OSHA and NIOSH guidelines to minimize risks.

For industrial applications, consulting health and safety professionals is advisable to ensure compliance with regulations.