Brass is one of the most commonly used metals in industries such as plumbing, electronics, and manufacturing, thanks to its excellent combination of strength, corrosion resistance, and ease of machining. However, not all brass is created equal. Depending on the intended application, brass can be processed in different ways to achieve varying mechanical properties. Two common forms of brass are annealed brass and hard brass. While they are both composed of copper and zinc, the difference between them lies in their hardness, flexibility, and the manufacturing processes used to produce them. Understanding these differences is crucial for choosing the right type of brass for your project.

Introduction

Brass, an alloy made primarily of copper and zinc, has been a staple in manufacturing and construction for centuries. Its versatility makes it suitable for a wide range of applications, but the material's properties can vary significantly depending on how it is processed. Annealed brass and hard brass are two popular forms, each with distinct characteristics that make them ideal for different uses. In this article, we’ll delve into what sets these two types of brass apart and explore their key differences in terms of properties, applications, and benefits.

Why Understanding Brass Types is Important

Durability: The choice between annealed and hard brass can affect the longevity and wear resistance of your product.

Machining and Fabrication: Some brass alloys are easier to work with than others, which can influence manufacturing costs and lead times.

Application-Specific Requirements: The right form of brass ensures optimal performance in specific uses, such as electronics, marine hardware, or musical instruments.

What is the Difference Between Annealed and Hard Brass?

1. Annealed Brass – Flexibility and Workability

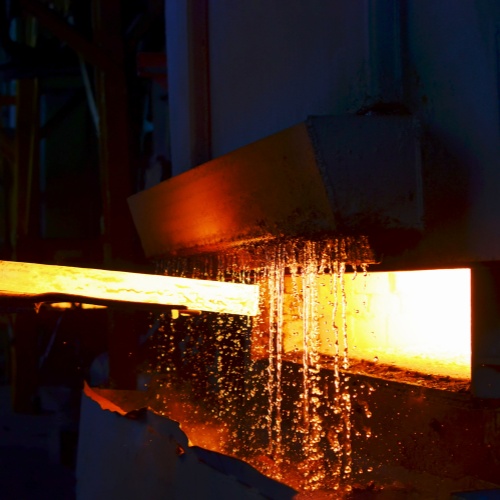

Annealed brass is brass that has been heat-treated to soften it, making it more malleable and easier to work with. During the annealing process, the brass is heated to a high temperature and then gradually cooled, which relieves internal stresses and reduces its hardness. This results in a brass material that is much more ductile, meaning it can be bent, shaped, or formed without cracking or breaking.

Properties:

Soft and Flexible

Increased Ductility

Lower Strength and Hardness

Better Formability

Common Applications:

Musical Instruments: Annealed brass is widely used in the production of instruments like trumpets and saxophones, where ease of shaping is crucial.

Plumbing Fittings: It is commonly used in plumbing because it can be easily bent to fit specific shapes and connections.

Electrical Components: Annealed brass is often used for connectors and terminals because it offers good electrical conductivity combined with ease of fabrication.

Example:

A company that manufactures brass pipes for plumbing systems uses annealed brass to ensure the material can be easily shaped into various fittings, ensuring a perfect fit for different pipe configurations.

2. Hard Brass – Strength and Durability

Hard brass, on the other hand, is not subjected to the annealing process and retains its natural hardness. This makes hard brass more resistant to wear, corrosion, and damage under high-stress conditions. However, the increased hardness also means that it is less ductile, which can make it more challenging to machine or form.

Properties:

Harder and Stronger

Reduced Ductility

Higher Tensile Strength

Better Resistance to Wear and Fatigue

Common Applications:

Gears and Bushings: Hard brass is used in high-wear applications like gears and bushings, where strength and durability are more important than flexibility.

Hardware Components: It is often used in the production of nuts, bolts, and other fasteners that need to endure heavy loads without deforming.

Marine Applications: Hard brass is ideal for parts exposed to corrosive environments, such as marine hardware, due to its superior resistance to corrosion.

Case Study: A marine company switched from annealed to hard brass for their boat fittings and noticed a 25% increase in part longevity, especially in saltwater environments where corrosion resistance is vital.

3. Key Differences at a Glance

| Property | Annealed Brass | Hard Brass |

| Hardness | Soft and ductile | Hard and resistant to wear |

| Machinability | Easy to machine and form | More difficult to machine and shape |

| Strength | Lower tensile strength | Higher tensile strength |

| Corrosion Resistance | Moderate, can be affected by environmental factors | Excellent, especially in marine environments |

| Common Uses | Musical instruments, electrical fittings, plumbing | Gears, bushings, fasteners, marine hardware |

Conclusion

The difference between annealed and hard brass lies primarily in their mechanical properties, which are determined by the processing methods used. Annealed brass is softer, more malleable, and ideal for applications where ease of shaping and forming is required. On the other hand, hard brass is stronger, more durable, and better suited for high-stress environments where wear resistance and strength are key. By understanding these differences, you can make informed decisions about which form of brass is best suited for your specific needs.

Key Takeaways:

Annealed Brass: Soft, flexible, and easy to work with, ideal for applications requiring shaping and bending.

Hard Brass: Strong, wear-resistant, and ideal for high-stress or corrosion-prone applications, but harder to machine.

Need Help Choosing the Right Brass for Your Project?

Whether you need annealed or hard brass for your manufacturing, plumbing, or industrial needs, selecting the right type can significantly impact the performance and longevity of your products. Contact us today for expert advice on selecting the best brass for your specific application!

Get in touch now for more information or assistance with your brass material needs!