Brass Plate/Sheet | Copper Plate/Sheet | Bronze Plate/Sheet

A brass plate is a metal sheet made from an alloy primarily consisting of copper and zinc, known for its durability, corrosion resistance, and aesthetic appeal.

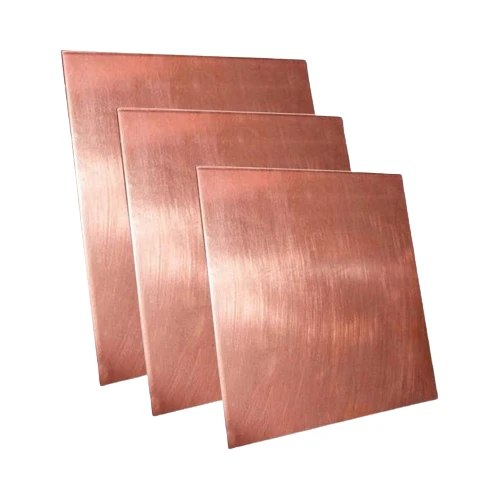

A copper plate is a flat, typically thin piece of copper metal, which is often used for its excellent thermal and electrical conductivity, as well as for decorative and industrial applications.

A bronze plate is a durable, corrosion-resistant metal sheet composed primarily of copper and tin, valued for its strength, casting capabilities, and historical significance in art and coinage.