C91700 Nickel Tin Bronze is a specific alloy with distinct properties. It is a combination of copper, nickel, and tin.

This nickel tin bronze offers excellent strength and hardness, which makes it suitable for applications where high mechanical performance is required. It also has good ductility, allowing it to be formed and shaped into various components.

The alloy shows remarkable corrosion resistance, enabling it to function well in a variety of environments, including those with exposure to moisture and certain chemicals. This makes it valuable in industries such as marine, aerospace, and automotive.

In marine applications, C91700 Nickel Tin Bronze is often used for propellers, shafts, and other components that need to resist corrosion from saltwater. In the aerospace field, it can be found in parts that require strength and durability.

It has good fatigue resistance, which is important for components that experience cyclic loading. Additionally, it has good thermal conductivity, which can be beneficial in certain applications.

For example, in some industrial machinery, the use of C91700 Nickel Tin Bronze for bearings or bushings helps ensure smooth operation and longevity. It can also be used in the manufacturing of valves and fittings where its combination of properties is advantageous.

Overall, C91700 Nickel Tin Bronze is a highly regarded alloy with a diverse range of applications due to its mechanical strength, corrosion resistance, and other valuable characteristics.

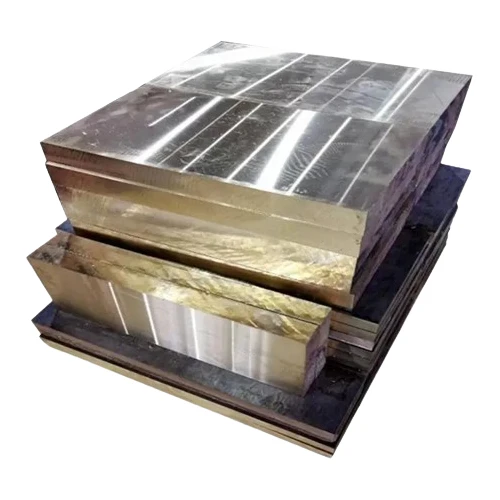

Typical Uses for C91700 Nickel Tin Bronze (Nickel Gear Bronze):

INDUSTRIAL: Worm Wheels, Worm Gears, Conprise Gears, Heavy Load, Relatively Low Speed Bearings

Specifications

| End Product | Specification |

| Centrifugal | ASTM B427 |

| Ingot | ASTM B30 |

| Sand | ASTM B427 |